If you are considering a UV Laser Marking Machine for your products, especially glass products, UV Laser should be the first choice.

We will explain why UV Laser Marking Machine is suitable for glass products for engraving. Types of UV Laser Marking Machine, advantages and disadvantages of UV Laser Marking Machine.

1.What is uv laser marking machine?

2.Types of UV Laser Marking Machine

2.1 Desktop UV laser Marking Machine

2.2 Portable UV Laser Marking Machine

2.3 Flying UV laser coding machine

3.Application industry of UV laser marking machine

4.Advantages of UV Laser Marking Machine

4.3 Wide range of applications

What is uv laser marking machine?

The UV laser marking machine is a member of the laser marking machine family, however it was created utilizing a 355nm UV laser.

In comparison to an infrared laser, the machine employs third-order intracavity frequency doubling technology, resulting in a 355 ultraviolet light focus spot that is exceedingly compact and belongs to a cold light source (cold marking).

Because it can greatly limit mechanical deformation of the material and has a low processing heat impact, it is mostly utilized for ultra-fine marking and engraving.

Especially suitable for marking and surface treatment of various materials such as glass, LCD, textile, thin ceramic, semiconductor silicon wafer, IC die, sapphire, polymer film, etc.

Types of UV Laser Marking Machine

UV laser marking machines are available in desktop and portable versions, as well as in flight.

Desktop UV laser Marking Machine

The whole machine is larger and heavier, mainly put in a fixed position, the worktable hit, you can carve some larger work, more convenient than the operation of small equipment.

Portable UV Laser Marking Machine

Portable UV laser marking equipment is specially developed for high precision marking, wide range of applications, simple, compact and flexible equipment needs.

Flying UV laser coding machine

Flying UV laser printer is a high-speed continuous marking machine designed to improve production efficiency. It is mainly used in production date, anti-counterfeiting, pharmaceutical and food packaging industry, etc.

Application industry of UV laser marking machine

The high-end ultra-fine processing market uses UV laser marking machines mostly for different glass ceramics, cell phone communication, gift packaging items, etc.

Glass-ceramics

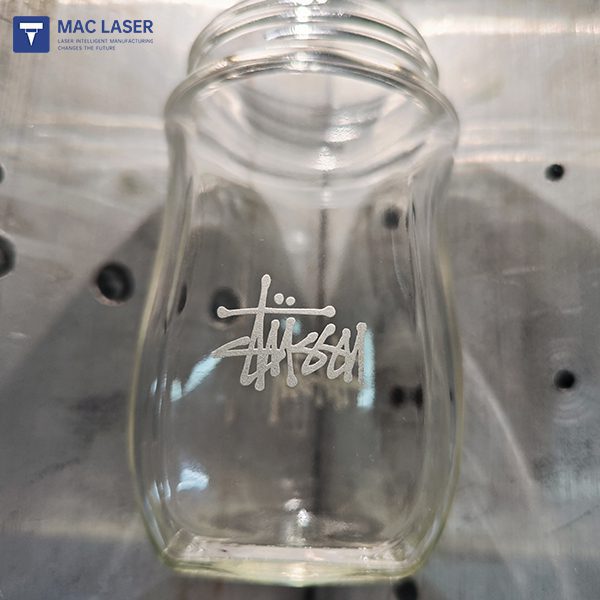

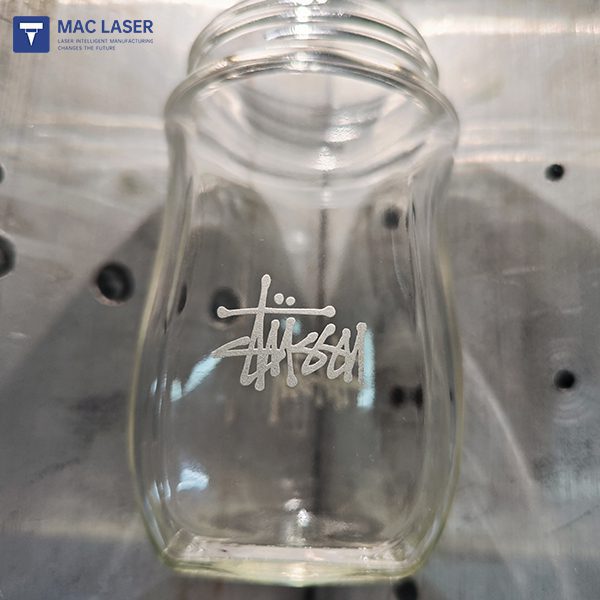

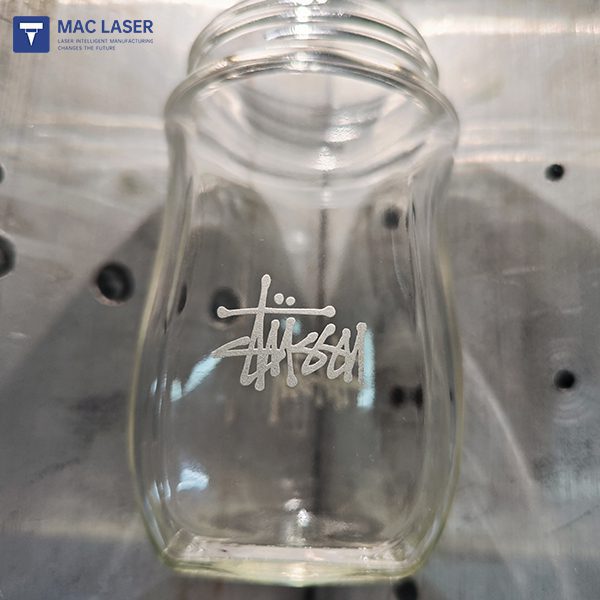

Using UV laser marking equipment, patterns are carved onto glass and ceramic materials.

Glass bottles, goblets, glass crafts, ceramic bowls and other glass ceramics are marked using UV laser marking machines.

Glass has the characteristic of fragility, so engraving on the surface of glass products is also more demanding in terms of craftsmanship.

UV laser marking machine is used without contact can be directly marked, short processing time, marking lines fine.

Because it uses an ultraviolet laser to emit ultraviolet wavelengths (355 nm) and then engrave a durable and environmentally hygienic pattern, it is ideal for marking glass surfaces with patterns or text messages.

Mobile Communication

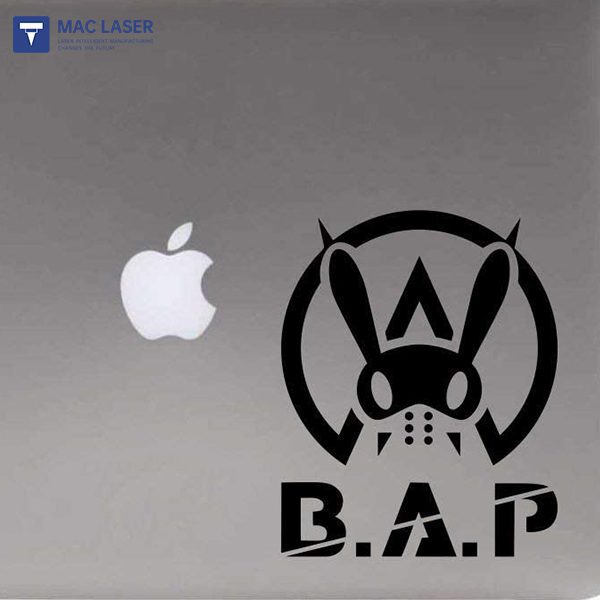

Headset cases, cell phones, tablet PCs and other cell phone communications use UV laser marking machines for pattern engraving.

Compared with traditional printing technology, UV marking is ink-free, delicate, not easy to erase, carved with high precision, high definition, permanent, and high anti-counterfeiting ability.

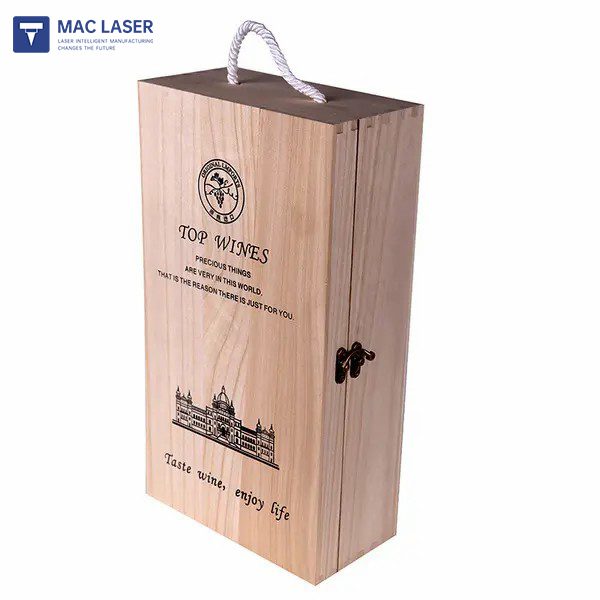

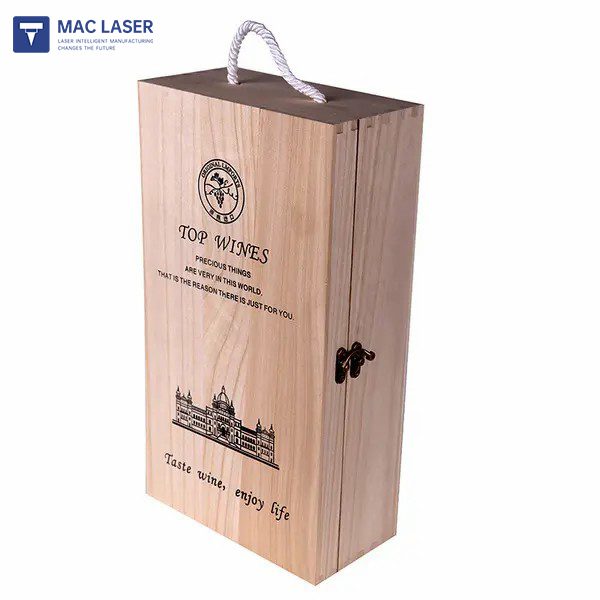

Gift wrapping

UV laser marking machine is the best choice for text marking of gift packaging.

Unlike self-adhesive labels, UV laser marking machines produce long-lasting marks that are generally not easily erased.

It is also more cost-effective and environmentally friendly overall because it doesn’t need any consumables and requires less maintenance.

The outer packaging of the product directly affects the consumer’s desire to buy.

It is possible to use a UV laser marking machine to engrave a range of patterns on packages that are not only clear and attractive but also have a strong information traceability function.

It greatly improves the efficiency of product packaging and makes quality monitoring and market circulation tracing more convenient.

Advantages of UV Laser Marking Machine

Fine Processing

UV lasers can lessen heat-induced material distortion for thermal processing devices like fiber lasers and CO2 lasers.

At the same time, the 355nm UV light has a small focus spot, which is also advantageous in fine processing.

Reduce pollution

With the help of laser energy, the bonds between atoms and molecules are broken, allowing the larger molecules to condense into smaller ones and evaporate or vaporize.

This technique is smoke-free and pollution-free, with a small focused spot and a mild influence on the heat-affected zone of the process.

Wide range of applications

At present, UV laser marking machine has been widely used in the fine processing industry: pharmaceuticals, food, cosmetics and other polymer materials packaging surface marking.

There are also optical devices, LCD liquid crystal glass, glassware surface, plastic keys, metal surface plating, electronic components, 3C products and many other industries.

Disadvantages of UV laser marking machine

The ideal working temperature for a UV laser marker is 10-35 degrees Celsius, and there should be no excessive dust in the environment.

Although using a UV laser marking machine doesn’t emit smoke or dust, there are still times when environmental cleaning and equipment upkeep are necessary.

Conclusion

UV laser marking is a flexible method that uses a variety of technologies to create marks that are accurate, long-lasting, and of high quality.

With high production rates, constant repeatability, mark durability, and minimal maintenance costs, this green technique is a great replacement for conventional marking technologies. As a result, it is a great option for your application.

Contact Mac Laser whenever you need high-quality laser marking services for your products, and we’ll help you get going!