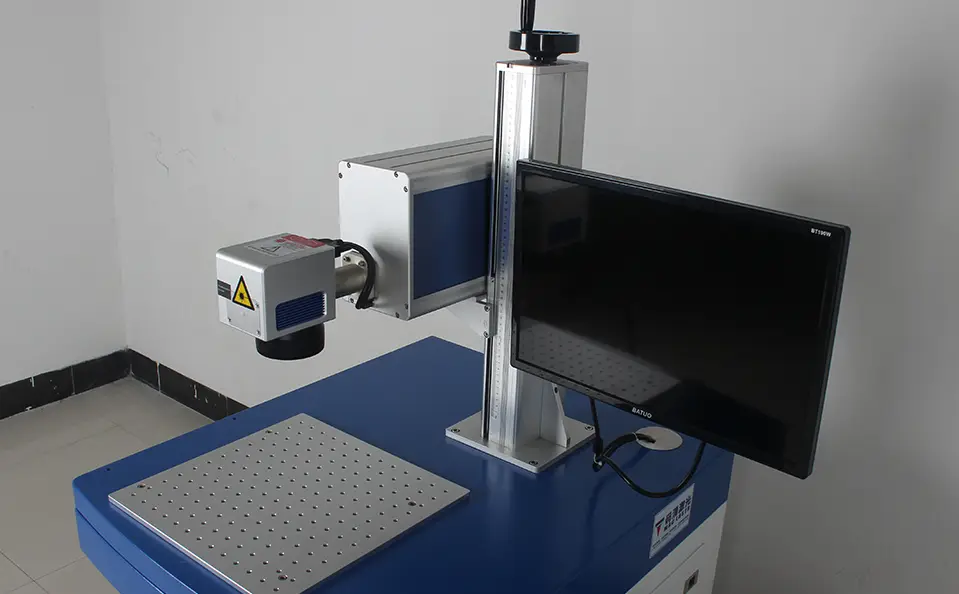

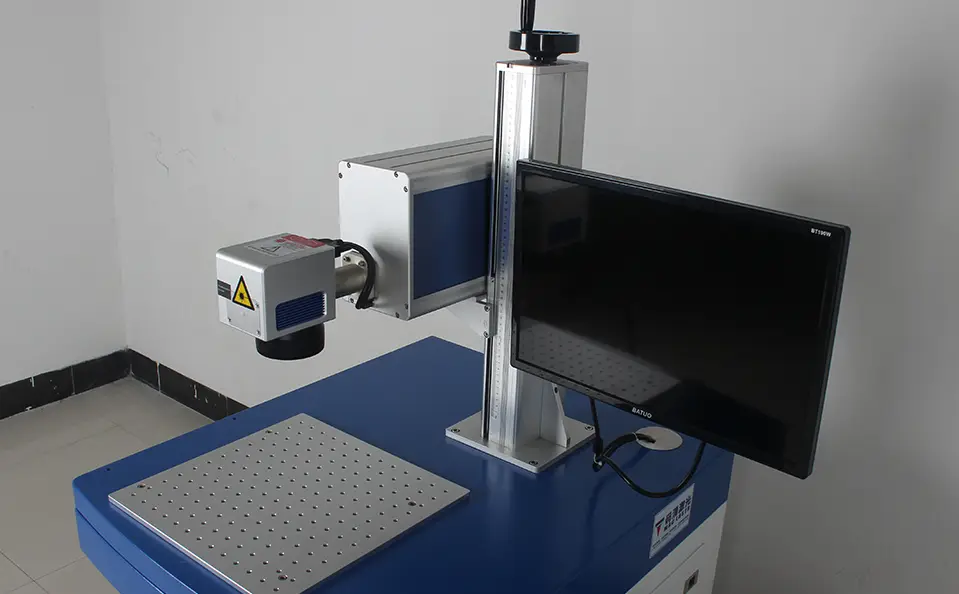

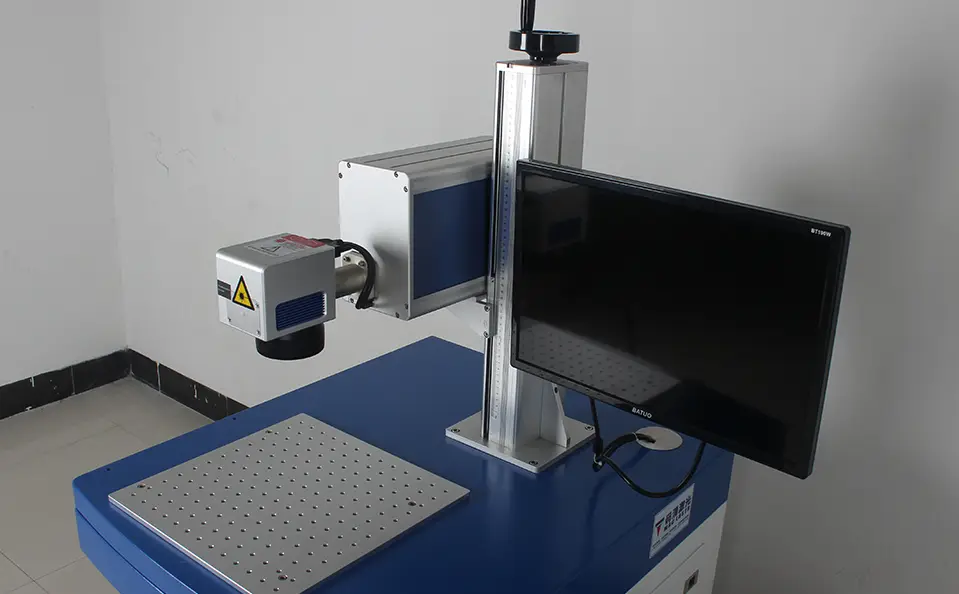

Description

ADVANTAGES OF MQ-T UV LASER MARKING MACHINE

Industrial computer host

Built-in Windows system, rich compatibility, supports a variety of software, can be connected to various expansion peripherals, durable, excellent heat dissipation

Cost-effective

The whole machine is small, flexible, convenient, powerful, and not limited by the use of space

Cooling water tank

The brand special domain industrial chiller is adopted, the cooling water is as stable as Mount Tai, and the temperature is cooled quietly, effectively avoiding the generation of air bubbles and prolonging the life of the UV laser marking machine equipment

High quality light source

Using advanced UV lasers, the output beam quality is good and the reliability is high

Advanced UV Laser Technology

The MQ-T UV Laser engraving Machine utilizes advanced UV laser technology to mark a wide variety of materials with precision and clarity. With a wavelength of 355nm, this machine is capable of producing highly detailed and permanent marks on materials such as plastics, metals, ceramics, and more. The UV laser engraving process produces minimal heat, which ensures that the materials being marked are not damaged during the process. This machine is perfect for industries that require high-precision marking on their products, such as medical devices, electronics, and automotive parts.

High-Speed and Easy-to-Use

The MQ-T UV Laser engraving Machine is designed for high-speed marking without compromising quality. Its high-speed scanning galvanometer system allows for fast and accurate engraving, increasing productivity while maintaining precision. This machine is also incredibly easy to use, thanks to its user-friendly interface and intuitive software. Users can easily upload and edit their designs, adjust engraving parameters, and start the engraving process with just a few clicks. With its efficient and user-friendly design, the MQ-T UV Laser Marking Machine is the perfect choice for businesses looking to increase their productivity and efficiency.

Versatile and Cost-Effective

The MQ-T UV Laser Engraving Machine is a versatile and cost-effective solution for businesses of all sizes. Its compact size allows it to be easily integrated into existing production lines, saving valuable floor space. This machine is also highly customizable, allowing users to adjust engraving parameters to suit their specific needs. The cost-effective UV laser marking process eliminates the need for expensive consumables such as inks and solvents, reducing overall operating costs. The MQ-T UV Laser Engraving Machine is an excellent choice for businesses looking to increase their bottom line without compromising on quality.

See for yourself and get a comprehensive test report.

TECHNICAL SPECIFICATIONS

| Model | MQ3A | MQ5A | MQ10A | |

|---|---|---|---|---|

| Laser parameters | Laser source model | S9-F-3 | S9-F-5 | S9-F-10 |

| Output Power | 3W | 5W | 10W | |

| Beam quality M2 | <1.2 | |||

| Laser wavelength | 355 nm | |||

| Pulse frequency | 10-200 kHz | |||

| Output beam diameter | 0.8±0.2 mm | |||

| Output power stability | <5 | |||

| Working life | About 20,000 hours | |||

| Optical properties | Marking range | 100~300mm (range optional) | ||

| Engraving depth | ≤1mm (depending on power and time) | |||

| Engraving speed | ≤10000mm/s | |||

| Repeat accuracy | ±0.002 | |||

| Minimum marking line width | 0. 01mm | |||

| Minimum character height | 0.03mm | |||

| Use environment | Cooling way | External water cooling (3W and 5W can be customized with air cooling) | ||

| System power supply | 500W / 220V / 50Hz (110V can be connected) | |||

| Temperature humidity | 5~35°,30% ≤RH 85% | |||

| Oil mist, condensation | Not allowed | |||

| Other parameters | Operating system | Windows operating system | ||

| File format | All fonts/types of WINDOWS operating system font library (standard USB input) | |||

| Dimensions | 800X660X1425 mm | |||

| Packing size | 860X730X1050 mm | |||

| Total Weight | About 100kg | |||

INDUSTRIAL MARKING APPLICATIONS

The MQ series ultraviolet laser engraving machine of Mac Laser is developed by using a 355nm ultraviolet laser. The material

has a high absorption rate of ultraviolet light and has a wider range of material adaptability. Ultraviolet light focusing

spot is very small, processing heat-affected zone is very small and it is more suitable for ultra-fifine marking of various

materials.

MORE LASER PRODUCT OPTIONS

MZF-H Portable UV Laser Marking Machine

MQ-M UV laser marking machine (DXT laser source)