INDUSTRIAL LASER WELDING: BOOSTING EFFICIENCY AND PRECISION IN MANUFACTURING

In the world of manufacturing, precision and efficiency are key to success. Industrial laser welding has emerged as a solution that provides both. By utilizing lasers, manufacturers are able to weld materials with greater accuracy and speed than traditional welding methods.

What is Laser Welding?

Laser welding is a process that uses a high-powered laser beam to join materials together. The laser beam is focused on the joint between the materials, which causes the materials to melt and then solidify, creating a strong bond.

This process is typically used to join metals, but it can also be used to join plastics and other materials. Laser welding technology is often used in the manufacturing of automobiles, aerospace parts, medical devices, and electronic components.

Types of Industrial Laser Welding

Nd:YAG Laser Welding: This type of welding uses a neodymium-doped yttrium aluminum garnet (Nd:YAG) laser to weld materials. It is commonly used for welding thin sheets of metal.

CO2 Laser Welding: This type of welding uses a carbon dioxide (CO2) laser to weld materials. It is commonly used for welding thicker materials.

Fiber Laser Welding: This type of welding uses a fiber laser to weld materials. It is commonly used for welding metals such as copper and aluminum.

Advantages of Laser Welding

Precision: The laser beam can be precisely focused on the joint between the materials, resulting in a more accurate weld.

Speed: Laser welding is faster than traditional welding methods, which can help to increase productivity.

Strength: The resulting weld is often stronger than welds created by traditional welding methods.

Efficiency: Industrial laser welding requires less energy than traditional welding methods, which can help to reduce energy costs.

Automation: Industrial laser welding machine can be easily automated, which can help to reduce labor costs.

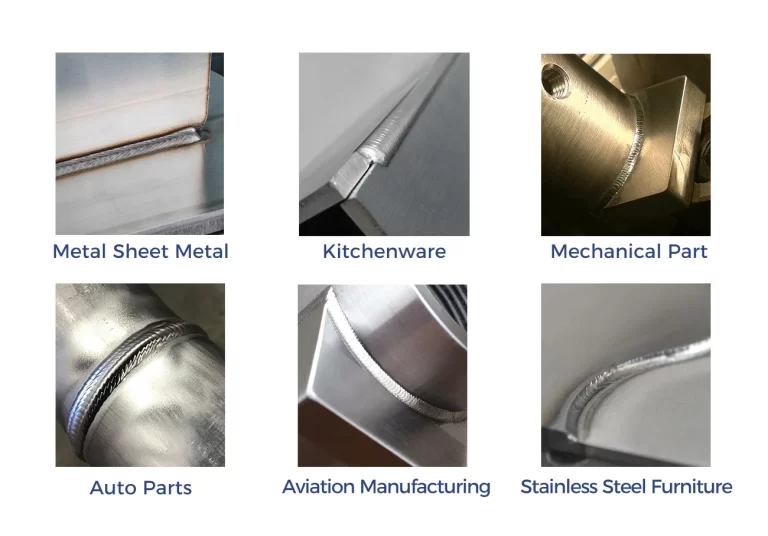

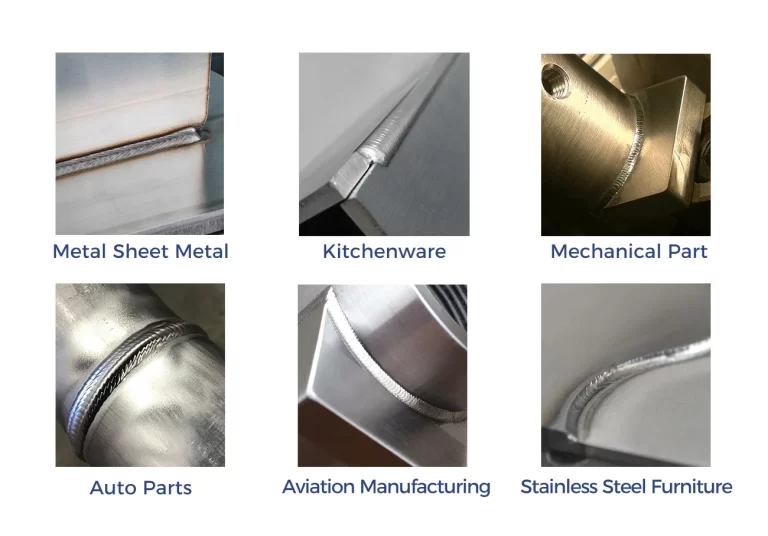

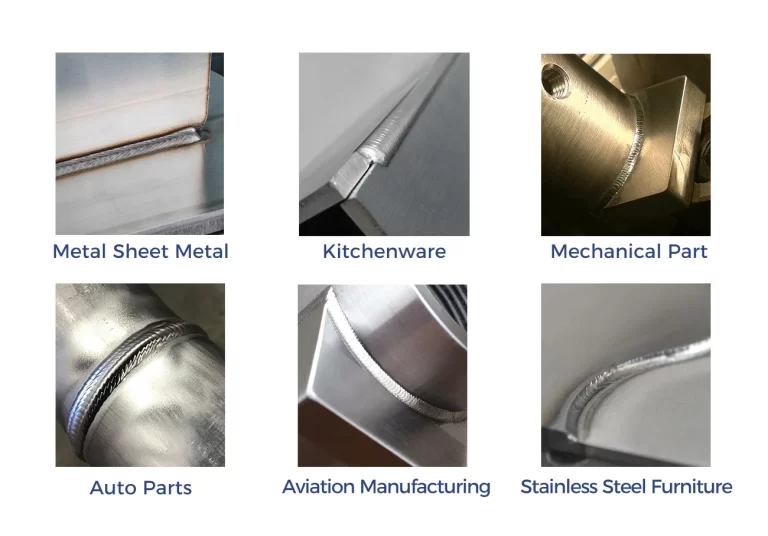

Applications of Industrial Laser Welder

Our Industrial laser welder is used in a variety of industries, including:

Automotive: It is used to weld car frames, engine components, and other parts.

Aerospace: It is used to weld aircraft frames, engines, and other parts.

Medical: Industrial laser welding machine is used to weld medical devices, such as pacemakers and surgical tools.

Electronics: It is used to weld electronic components, such as circuit boards and sensors.

FAQs

Is laser welding safe?

Yes, laser welding can be safe if proper safety precautions are taken and personnel are properly trained.

What materials can be welded with laser welding?

Laser welding is commonly used for welding metals, but it can also be used for welding plastics and other materials.

How fast is laser welding?

Laser welding methods is typically faster than traditional welding methods, which can help to increase productivity.

Is laser welding equipment expensive?

Industrial laser welding equipment can be expensive, especially for small-scale operations.