INDUSTRIAL LASER SOLUTIONS FOR ELECTRONICS

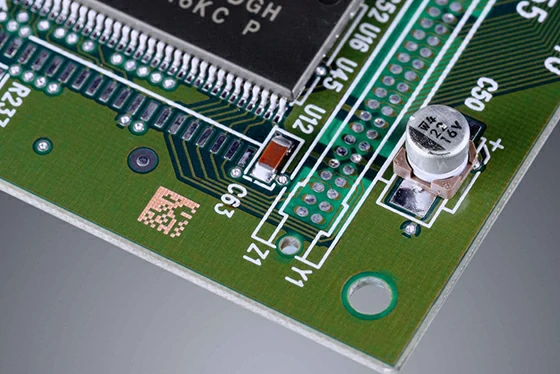

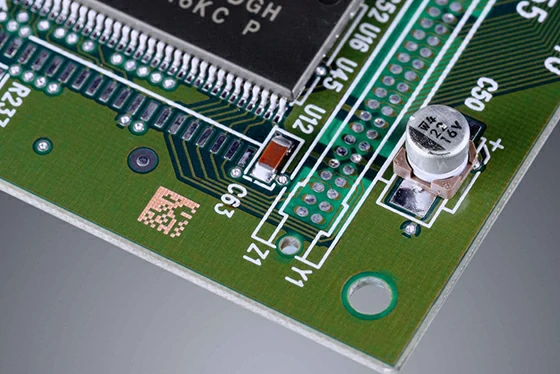

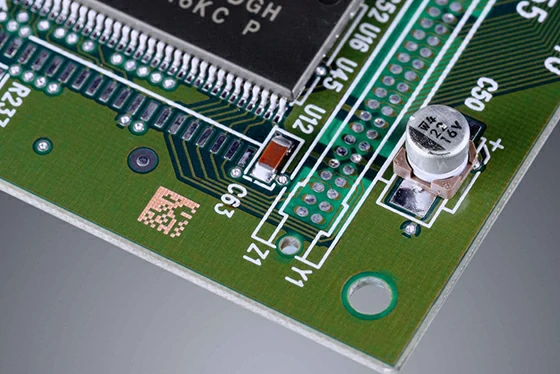

Manufacturers in the electronics industry and semiconductor industry often prefer to use laser marking due to its ability to produce high-quality, clear marks and the capability to engrave even the smallest components. For original equipment manufacturers (OEMs), it is essential to have product identification and traceability, which is why laser marking is a critical aspect of the production process.

When it comes to marking sensitive electronic components, marking lasers are the preferred tool. These lasers offer stable laser properties and targeted energy input, which ensures reliability, permanence, and traceability, even when used with different types of component materials.

APPLICATIONS FOR ELECTRONICS DEVICE MARKING

Laser marking machines can handle a wide variety of materials and applications. MACLASER provides traceability systems for electronic components, including:

- PCBs

- Semi-conductors

- Flame Retardant Plastics

- Breakers

- Meter housings

- Molded plastic housings

- Connectors

- PLCs

FEATURED APPLICATIONS FOR THE ELECTRONICS INDUSTRY

BENEFITS OF LASER TECHNOLOGY FOR ELECTRONICS

PERMANENT ALTERNATIVE TO INKJET & LABELING

Unlike inkjet and labeling methods, laser marking technology offers permanent marks on electronic components. The marks won't fade, smudge, or rub off over time, ensuring clear identification and traceability.

HIGH QUALITY, CONTRAST MARKS

Laser marking system can produce high-quality, high-contrast marks on electronic components. This is particularly useful for parts that need to be read by machines or humans, as the marks can be clear and easy to read even on small components.

MAKE YOUR MARK IN SMALL AREAS

Laser technology can make precise marks in small areas, even on components with complex shapes or hard-to-reach areas. This makes it an ideal choice for marking electronic components that have limited space for identification.

RECOMMENDED LASER SOLUTIONS

UV-R Serial Flying UV Laser Marking Machine

KX-K Pulse Fiber Laser Marking Machine