Industrial Laser Marking

Parts Identification and Traceability for Every Industry

Laser-based solutions can be used for part identification and traceability in a variety of industries, from manufacturing to healthcare to aerospace.

By using lasers to mark parts with unique identifiers such as barcodes, serial numbers, or data matrices, it becomes easier to track them throughout the supply chain and verify their authenticity. Laser marking can also improve efficiency and reduce the risk of errors compared to traditional marking methods.

Deep Dive: The Industry's Unique Marking Requirements

Explore our product capabilities for your industry application.

BATTERIES

OIL & GAS

AUTOMOTIVE

METALS

AGRICULTURE & HEAVY

AEROSPACE

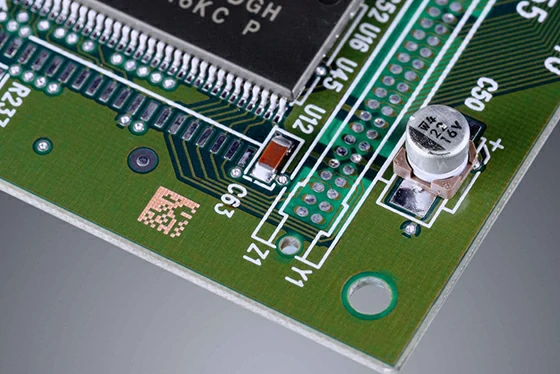

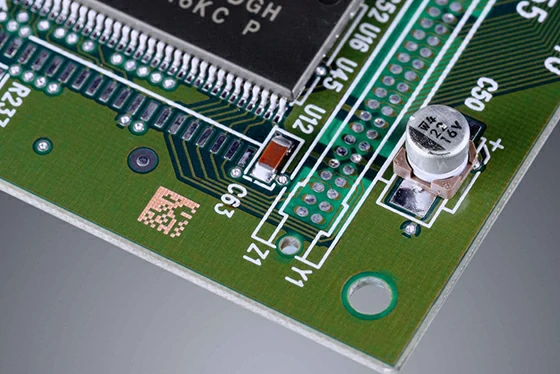

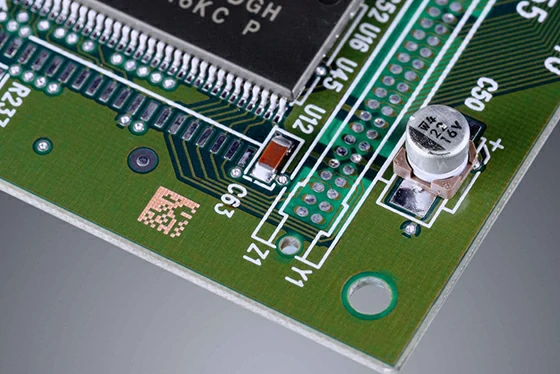

ELECTRONICS

MEDICAL

Our Industrial Laser Marking Types

Fiber Laser Marking

Fiber laser marking technology uses a high-powered laser beam generated by a fiber optic cable. This type of laser is ideal for marking metals and plastics and can produce high-quality, permanent markings.

CO2 Laser Marking

CO2 laser marking technology uses a laser beam generated by a gas-filled tube. This type of laser is suitable for marking plastics, paper, and wood, and can produce high-contrast markings.

UV Laser Marking

UV laser marking technology uses a laser beam with a shorter wavelength, allowing it to mark materials that are difficult to mark with other types of lasers, such as glass and certain plastics.

Factors to Consider When Choosing an Industrial Laser Marking System

– Material type and thickness

– Marking requirements, including size, depth, and contrast

– Production volume and speed

– Cost of the system and maintenance

– Compatibility with existing production equipment

– Ease of use and programming