LASER MARKING & CUTTING & CLEANING & WELDING SOLUTIONS

MacLaser is a leading international laser manufacturer that can provide you with laser marking, cutting, cleaning and welding solutions. MacLaser’s vision is to push the limits of laser technology and set new standards in the industry.

INNOVATIVE PROCESSES

INLINE SOLUTIONS

GUARANTEED SAFETY

OUR CLIENTS

Why Choose MacLaser?

COMMITMENT

Our top priority is delivering outstanding solutions and a top-notch customer experience. We strive for excellence in every aspect and collaborate as a team to ensure every project’s success.

INNOVATION

MacLaser combines expertise, creativity and passion to lead in laser tech and drive innovation in manufacturing.

PASSION

Our team thrives on challenges, collaboration, and self-improvement with a work hard, play hard mentality.

SUSTAINABILITY

Dedicated to a sustainable future, we drive green technology development and eco-friendly initiatives in manufacturing.

OUR LASER MACHINES

LASER MARKING

MACHINES

Our laser marking machines ensure clean processing with minimal contamination and are certified for safety. Whether you need to minimize impact on cycle time, mark multiple parts, minimize a machine’s footprint, or manage part positioning variations, we have the perfect solution for you.

OUR LASER MACHINES

LASER CLEANING

MACHINES

Our laser cleaning machines are complete solutions featuring chemical-free, laser-safe, performance-optimized features and more. They are ready for a variety of material processing needs in various industries with high temperature and high pressure environments such as aerospace, automotive, military defense, power generation, nuclear facilities, maintenance facilities, etc. In high-volume production lines, they provide a high return on investment and achieve excellent cleaning and texturing quality.

OUR LASER MACHINES

LASER CUTTING

MACHINES

Our laser cutting machine is a complete solution with features such as easy cutting, high positioning accuracy, and airtight safety. Each machine is designed to give you an affordable laser cutting solution for optimal cutting results.

OUR LASER MACHINES

LASER WELDING

MACHINES

Our laser welding machines are complete solutions with features such as high precision, perfect welds, and high strength. They are ready for precision parts, medical instruments and solenoids and machined parts. In high-volume production lines, they provide a high return on investment and enable increased productivity.

Laser applications

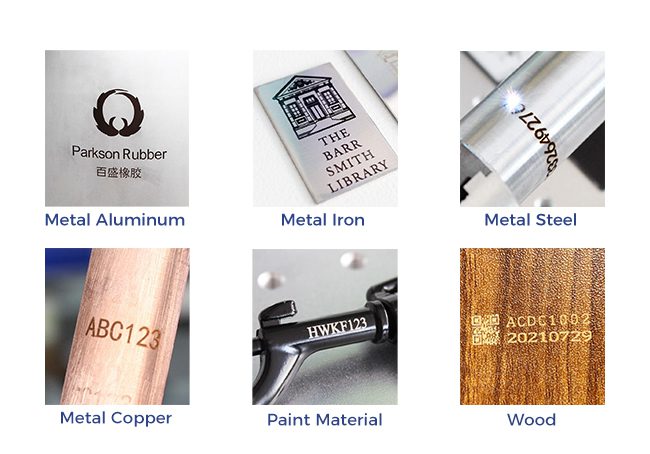

LASER MARKING

MacLaser provides top-notch laser marking solutions for permanent identification and traceability of parts. Our lasers are the fastest in the market, ensuring efficiency and preventing production bottlenecks. With various options to enhance marking quality, and advanced protection codes for surface treatments, MacLaser is the preferred choice for superior laser marking.

Laser applications

LASER CLEANING

MacLaser offers effective laser cleaning solutions that eradicate various types of contaminants like rust, oxide, paint, and electrolyte from metal surfaces. Our advanced technology ensures that contaminants are removed with precision and repeatability, leaving the metal intact. With the option of up to 3kW of power, our cleaning speed is unparalleled and can be adjusted to meet your specific needs.

Laser applications

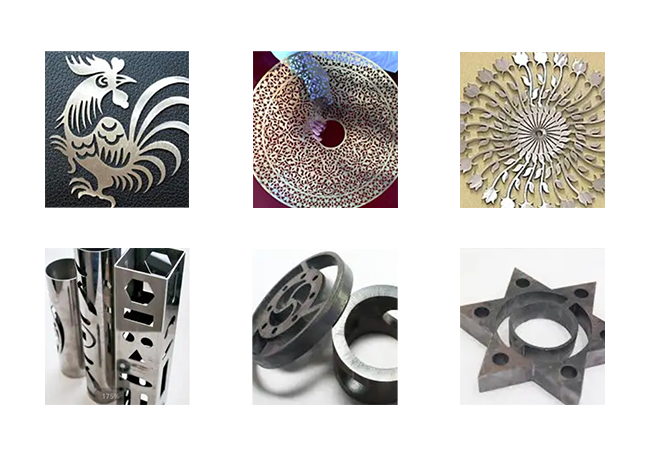

LASER CUTTING

Our laser cutting machine provides precise and efficient cuts for a wide range of materials. The machine’s advanced technology allows for cutting with high accuracy and speed, making it ideal for industries such as automotive, aerospace, and medical devices. For example, in the automotive industry, the laser cutting machine has been used to create intricate designs for car interiors, saving time and increasing production efficiency.

Laser applications

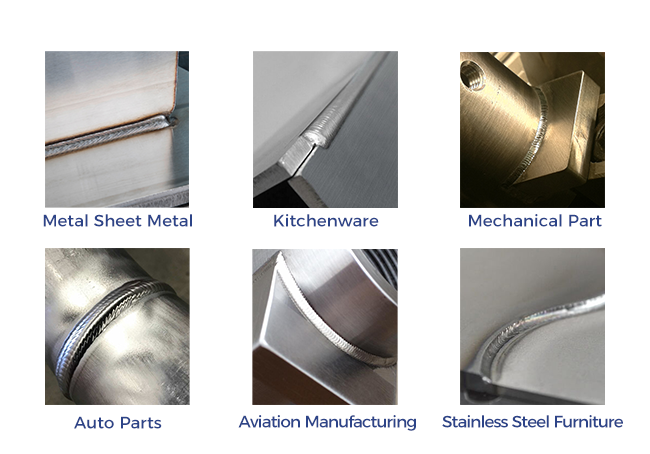

LASER WELDING

Our laser welding machine is a versatile solution for welding a wide range of materials. Its advanced technology allows for precise and consistent welds, making it suitable for a variety of industries, including jewelry, electronics, automotive, and medical devices. The laser welding machine’s ability to handle delicate and intricate designs, as well as its speed and efficiency, make it a popular choice for a wide scope of welding applications.

About Mac Laser

Founded in 2008, MAC LASER is a pioneering high-tech company specializing in the development of laser marking machines and other laser processing equipment.

Our extensive range of solutions includes laser marking devices, precision laser cutting devices, laser welding machines, laser cleaning devices, CCD positioning precision marking equipment, intelligent industrial manipulators, and customized non-standard assembly line automation for companies. We also offer CNC integration services to help companies optimize their production processes.

Seize the Laser Marking Advantage: Join us as a Strategic Distribution Partner!

At MAC LASER, we offer best-in-class industrial laser marking systems that are leaders in quality, durability and performance.

BLOG POSTS

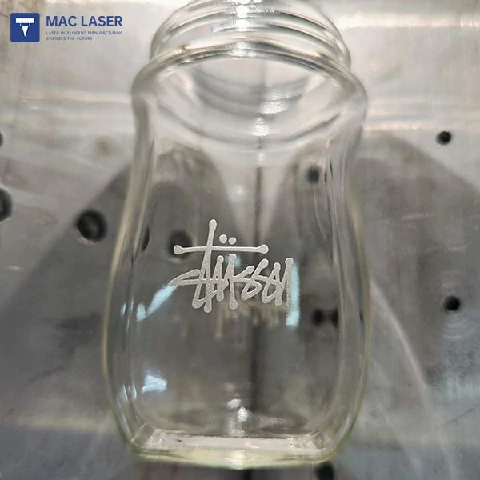

If you are considering a UV Laser Marking Machine for your products, especially glass products, UV Laser should be the first choice.

This is a complete guide to UV laser marking machine in 2023.So if you want to know:

Whether your own product is suitable for a UV laser marking machine

What is the difference between UV laser and fiber laser

Want to learn more about UV laser marking machines

FAQs

MACLASER provides free consultation, business plan, quotation, and sales services for the sold machines and accessories, and provides technical support such as transportation, distribution, installation, commissioning, operation, and maintenance for the sold machines, and provides lifelong installation, commissioning, and maintenance services . Software Maintenance Services.

Using a marking machine is not difficult. You’ll find all the guidance you need in the operating manual and videos.

Yes to both! The software is provided FREE of charge and it is in English.

Marking machines make “marks” or “stamps” or “engraves” on metallic or non-metallic materials or devices. Examples of metals: stainless steel, aluminum, copper, brass, carbon steel, etc. Non-metal: plastic, glass, ceramics, resin, wood, cardboard, etc. The marking machine used depends on the material and product to be marked.